De-Ionising System with Manual Head

- Standard delivery time: 2-4 business days

- Receive free shipping on orders above $150

Shipping & Delivery

Shipping & Delivery

Shipping Rates

- Free delivery on all orders over $200.

- Flat fee of $15.95 for Local North Island orders under $200.

- Flat fee of $22.95 for Rural North Island orders under $200.

- Flat fee of $28.00 for Local South Island orders under $200.

- Flat fee of $34.00 for South Island orders under $200.

- We can only deliver to physical addresses — unfortunately, P.O. Boxes are excluded.

Exclusions

- Free shipping does not apply to pre-order items.

- Shipping costs for pre-orders will be calculated at the time of your inquiry, based on your location within New Zealand.

- If you require urgent delivery, we may be able to arrange airfreight. Additional charges will apply. Please contact us for details.

Delivery Timeframes

- Standard delivery is usually 2–4 business days (Mon–Fri) from the date of dispatch, excluding public holidays.

- Delivery times may vary depending on the size of the item and your location.

Returns & Refunds

Returns & Refunds

If we send the wrong item, we cover return costs. If you ordered incorrectly, you’ll need to return at your cost.

If you wish to return or exchange an item, please email us at info@waterfilters.co.nz within 7 days of receiving your order to obtain a Return Authorisation Number (RNA). Please do not return your product until you have received this number.

Returns & Exchanges

-

If we send the wrong item (and your order was placed correctly):

We will cover the cost of return shipping. A pre-paid return label will be issued, and the correct item will be dispatched. -

If you ordered the wrong item (and we supplied what was ordered):

You will be responsible for the cost of return shipping. If you would like us to provide a return label, we can do so, but the cost will be deducted from your refund or charged separately. -

All returns (whether for exchange, credit, or refund) must be unused, undamaged, and in saleable condition. Items with signs of use or damage will not be accepted and will be returned to you.

-

We strongly recommend using a tracked courier service for all returns, as we cannot be held liable for parcels lost or damaged in transit.

-

Refunds will be processed via the original form of payment and will cover the cost of the returned item(s) only. Please allow up to 14 business days from receipt of your return for processing.

Cancellations

If you wish to cancel an order, please contact us within 24 hours of placing it. Orders are processed quickly and in some cases may not be able to be cancelled once dispatched. If cancellation is no longer possible, please follow the returns process above once your order arrives.

Faulty Products

If you have received a faulty product, please contact us to arrange a return service.

-

Faulty items (caused by a manufacturing defect, not wear and tear or misuse) will be replaced or refunded at no cost to you, following our assessment.

-

Consumables (e.g. cartridges, lamps, media) are covered for manufacturing defects but not for lifespan variation, as water quality and usage conditions differ.

Warranty

We stand behind the quality of our products and offer the following warranty:

-

Systems and parts (excluding consumables): 2 years from purchase, subject to correct installation and conditions of use.

-

Consumables: Covered only for manufacturing defects (must be reported within 7 days of receipt).

During the warranty period, any approved faulty component (excluding consumables) will be replaced free of charge, subject to stock availability.

To make a warranty claim:

-

Contact us via email or phone.

-

Provide proof of purchase.

-

Obtain a Return Authorisation Number before sending any items back.

All warranty work or returns must be approved before costs are incurred.

Your Consumer Rights

Our goods come with guarantees that cannot be excluded under the Consumer Guarantees Act 1993 (NZ). You are entitled to a replacement or refund for a major failure, and compensation for other reasonably foreseeable loss or damage. You are also entitled to have goods repaired or replaced if they fail to be of acceptable quality and the issue is not a major failure.

Waterfilters.co.nz Guarantee

We are committed to providing quality products, clear after-sales support, and excellent customer service. If something isn’t right, let us know and we’ll work to resolve it promptly.

Description

Description

APPLICATIONS

-

Laboratories

- Dentists

GENERAL INFO

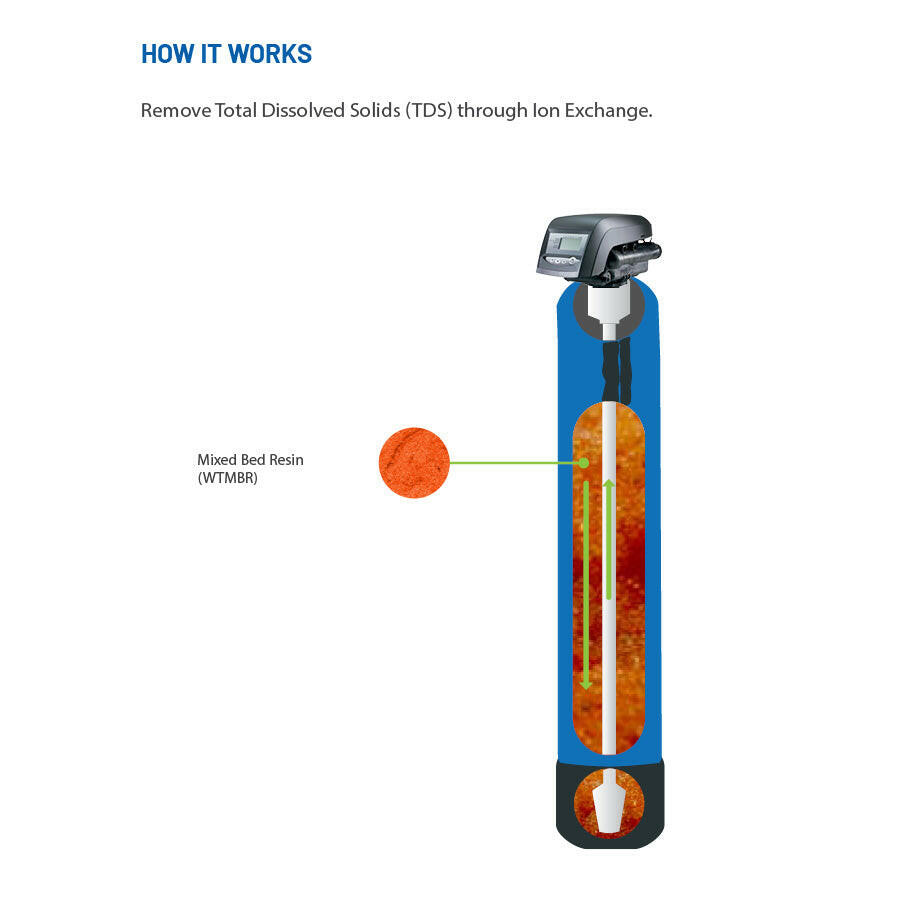

De-Ionisation is a physical process that uses specially manufactured ion-exchange resins that bind to and filter out the mineral salts from water. The majority of water impurities are from dissolved salts. De-Ionisation produces high purity water that is generally similar to distilled water, and this process is quick and without the problems associated with scale build-up. This high purity De-Ioniser scavenges all remaining mineral salts from a water supply in exchange for hydroxyl ions (which convert back to pure water).

FEATURES | BENEFITS

Achieves low operational costs and long periods between resin changes. It uses high quality, non regenerating, mixed bed resin and is suitable for small to medium flows.

SEDIMENT PRE-FILTRATION

Sediment pre-filtration is advisable to optimise resin life. Especially those applications with significant levels of suspended solids.

STRUCTURAL® POLYGLASS TANK

Pentair® Structural Polyglass Vessels have been the industry standard for quality and performance for over 30 years. Featuring a one-piece, seamless, high-density polyethylene liner and an encapsulated, leak-free engineered polymer inlet, Structural Polyglass Vessels were designed to provide you with years of worry-free performance.

OPERATING PARAMETERS (TANK)

-

Maximum operating pressure – 150 psi

- Maximum operating temperature – 49°C

AUTOTROL® 263-268 (INTELLIGENT CONTROL VALVE)

- Time-tested Duraflow flapper provides frictionless sealing for longer service life

- Fiber-reinforced polymer valve body for superior strength and durability, non-corrosive, and UV-resistant

- Optical sensor for precision cycle positioning

- Designed with double backwash for reduced hardness leakage

- Fully adjustable 5 or 8 cycle control for an efficient and reliable water treatment system

- Continuous service flow rate of 95 LPM with a backwash of 76 LPM

- Backwash capability accommodates filter up to 18” in diameter

- Supercapacitor for keeping time of day during a power outage

-

Environmental protective cover for water resistance, corrosion resistance, and UV stability

Programming is stored in memory and will not be lost due to power outages -

History data for valve performance

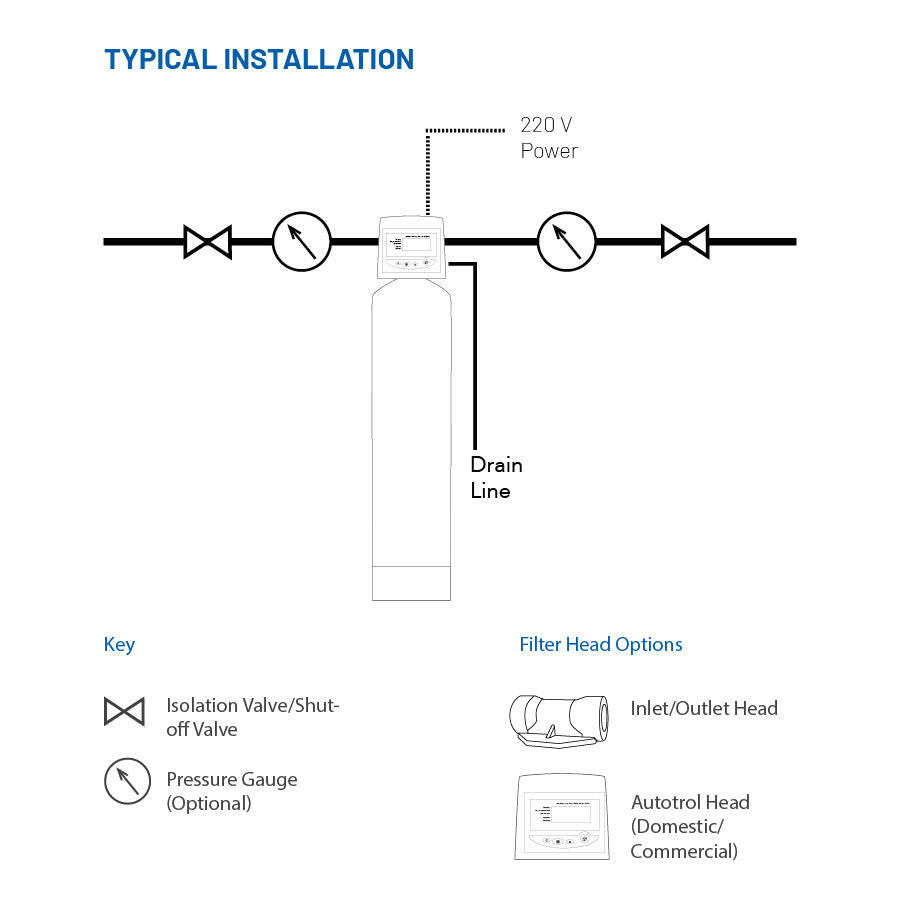

NOTE: Inlet/Outlet Head available for 7” - 9” Tanks

DE-IONISING SYSTEM

MEDIA

QUANTITIES

Code

Description - Tank Size Inches (DxH)

Typical Flow Rate

Inlet/Outlet

Mixed Bed Resin

(WTMBR)

“Polywound” Tanks

Litres/Minute

Inches

Litre

DIM-717

"Upflow Head" - 7" x 17"

3/4”

8

DIM-735

“Upflow Head” - 7” x 35”

3/4”

15

DIM-935

“Upflow Head” - 9” x 35”

3/4”

25

DIA-1054

“Autotrol Head” - 10” x 54”

1”

50

DIA-1252

"Autotrol Head" - 12” x 52”

1”

70

DIA-1465

“Autotrol Head” - 14” x 65”

1”

115

DIA-1665

“Autotrol Head” - 16” x 65”

1”

150

AUTOTROL HEAD

“PENTAIR” 263 Performa Filter Valve with 742F Logix Time Clock Controller

Valve Body

Glass-filled thermoplastic - NSF listed material

Rubber Components

Compounded for cold water – NSF Listed material

Operating Pressure

20-120 psi (1.38-8.27 bar)

Maximum operating pressure

150 psi

Maximum operating temperature

120° F

Hydrostatic Pressure

300 psi (20.69)

Water Temperature

2°- 38°C

Ambient Temperature

2°- 48.9°C

Tank Thread

2-1/2” – 8, male

Inlet/Outlet Threads

1-3/4”-12 UNC-2A male

Drain Line

3/3” NPT, male

Width x Height

37.8 cm x 21.5 cm

Riser Tube Dia.

27 mm

Riser Height Above top of tank

0.5” (+/- 0.5”)

Service flow rate

5 psi (1.03 bar) drop 25.0 gpm (5.7 m3/h)

Backwash flow rate

25psi (1.72 Bar) drop 20.0 gpm (4.5 m3/h)

Service

Cv = 6.50 (Kv = 5.6)

Backwash

Cv = 4.00 (Kv = 3.5)

Controller Operating Voltage

12 volt– AC

Input Supply Frequency

50 or 60 Hz

Moter Input Voltage

12 volt– AC

Controller System Power Consumption

3 watts average

Transformer Output Voltage

12 volt– AC 400mA

Transformer Input

230 volt– AC 50/60 Hz

*Recommend use of outdoor cover for direct sunlight applications

OPERATION AND MAINTENANCE

Operation and maintenance are simple: After the initial set-up, the system is virtually self-sustained. With the automatic head, back-flushing and clearing of trapped contaminants occur automatically. Media is replaced as TDS issues arise. We recommend installing a TDS meter inline to monitor the water quality.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.